- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-05 Origin: Site

In the realm of electronic devices, achieving electromagnetic interference (EMI) compliance is crucial for ensuring that products operate efficiently without causing or being affected by unwanted electromagnetic disturbances. One of the key components that aid in achieving EMI compliance is the use of EMC-Filter Capacitors. These capacitors play a vital role in filtering out unwanted noise and ensuring that electronic devices meet the necessary regulatory standards. This article delves into the mechanisms by which EMC filter capacitors improve EMI compliance, their applications, and the benefits they offer to electronic products.

Electromagnetic interference (EMI) refers to the disturbance that affects an electrical circuit due to electromagnetic radiation emitted from an external source. This interference can degrade the performance of the circuit or even lead to complete malfunction. Electromagnetic compatibility (EMC), on the other hand, is the ability of a device to operate correctly in its electromagnetic environment without introducing intolerable electromagnetic disturbances to anything in that environment. Achieving EMC is essential for the reliability and functionality of electronic devices, especially in today's interconnected world where numerous devices operate in close proximity.

EMC-filter capacitors are designed to suppress high-frequency noise in power lines and signal lines. They are crucial in preventing EMI from affecting the performance of electronic devices. These capacitors are typically used in conjunction with other components such as inductors and resistors to form a filter circuit that attenuates unwanted frequencies while allowing the desired signals to pass through. The effectiveness of these capacitors in improving EMI compliance is largely due to their ability to provide low impedance paths for high-frequency noise, thereby shunting it away from sensitive components.

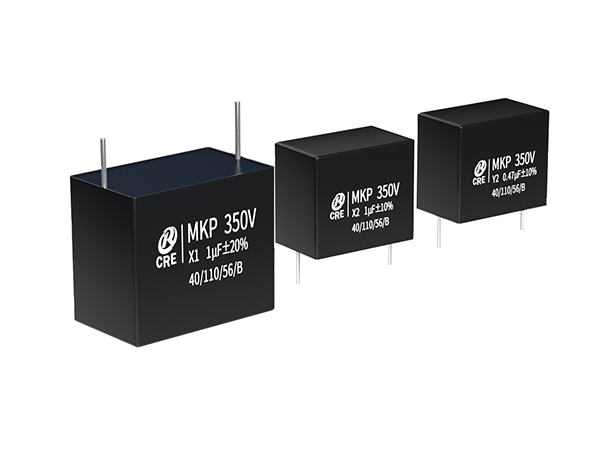

There are several types of EMC-filter capacitors, each suited for different applications and environments. The most common types include ceramic capacitors, film capacitors, and electrolytic capacitors. Ceramic capacitors are widely used due to their small size and excellent high-frequency performance. Film capacitors offer high stability and low loss, making them ideal for applications requiring high reliability. Electrolytic capacitors, while not as effective at high frequencies, are often used in power supply applications due to their high capacitance values.

Ceramic capacitors are popular in EMI filtering applications due to their low cost, small size, and excellent performance at high frequencies. They are typically used in bypass and decoupling applications to shunt high-frequency noise to ground. The dielectric material used in ceramic capacitors provides a high dielectric constant, allowing for a compact design with significant capacitance values. This makes them ideal for use in compact electronic devices where space is at a premium.

Film capacitors are known for their stability, low loss, and long lifespan. They are often used in applications where reliability is critical, such as in automotive and industrial electronics. Film capacitors are constructed using thin plastic films as the dielectric, which provides excellent electrical properties and high insulation resistance. These capacitors are particularly effective in filtering applications where low loss and high stability are required.

Electrolytic capacitors are typically used in power supply applications where high capacitance values are needed. They are less effective at high frequencies compared to ceramic and film capacitors, but their ability to store large amounts of charge makes them useful in applications where large current surges need to be smoothed out. Electrolytic capacitors are often used in conjunction with other types of capacitors to provide a comprehensive filtering solution.

EMC-filter capacitors are used in a wide range of applications across various industries. In consumer electronics, they are used to suppress noise in audio and video equipment, ensuring clear and uninterrupted performance. In the automotive industry, EMC-filter capacitors are essential for ensuring that electronic control units (ECUs) operate without interference from other electronic systems in the vehicle. In industrial applications, these capacitors help maintain the reliability of machinery and equipment by preventing EMI from affecting sensitive control systems.

In consumer electronics, EMC-filter capacitors are crucial for ensuring that devices such as televisions, radios, and computers operate without interference. These capacitors help filter out unwanted noise that can affect the quality of audio and video signals, ensuring that consumers enjoy a high-quality experience. By improving EMI compliance, manufacturers can ensure that their products meet regulatory standards and provide a reliable performance.

The automotive industry relies heavily on electronic systems for everything from engine control to infotainment systems. EMC-filter capacitors play a vital role in ensuring that these systems operate without interference from other electronic components in the vehicle. By suppressing EMI, these capacitors help maintain the reliability and safety of automotive systems, which is crucial for the overall performance of the vehicle.

In industrial settings, EMC-filter capacitors are used to protect sensitive equipment from EMI that can cause malfunctions or damage. These capacitors are often used in machinery and control systems to ensure that they operate reliably and efficiently. By preventing EMI from affecting these systems, EMC-filter capacitors help maintain the productivity and safety of industrial operations.

The use of EMC-filter capacitors offers several benefits for electronic products. By improving EMI compliance, these capacitors help ensure that devices meet regulatory standards, which is essential for gaining market approval and avoiding costly redesigns. Additionally, by suppressing unwanted noise, EMC-filter capacitors enhance the performance and reliability of electronic devices, leading to increased customer satisfaction and reduced warranty claims.

Achieving regulatory compliance is a critical aspect of bringing electronic products to market. EMC-filter capacitors help manufacturers meet the stringent requirements set by regulatory bodies, ensuring that their products can be sold in various markets around the world. By incorporating these capacitors into their designs, manufacturers can avoid costly delays and redesigns associated with failing to meet EMI standards.

By suppressing unwanted noise, EMC-filter capacitors enhance the performance of electronic devices. This leads to improved signal quality, reduced interference, and increased reliability. For consumers, this translates to a better user experience, with devices that operate smoothly and efficiently. For manufacturers, enhanced performance means fewer returns and warranty claims, leading to increased profitability.

Reliability is a key factor in the success of electronic products. EMC-filter capacitors help ensure that devices operate consistently and without interruption, even in environments with high levels of electromagnetic interference. This increased reliability leads to higher customer satisfaction and brand loyalty, as consumers can trust that their devices will perform as expected.

In conclusion, EMC-Filter Capacitors play a crucial role in improving the EMI compliance of electronic products. By suppressing unwanted noise and ensuring that devices meet regulatory standards, these capacitors enhance the performance, reliability, and marketability of electronic devices. As the demand for electronic products continues to grow, the importance of achieving EMI compliance will only increase, making EMC-filter capacitors an essential component in the design and manufacture of modern electronic devices.