- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-06 Origin: Site

Modern power electronics systems are built for speed, efficiency, and precision. From high-speed trains to industrial converters and renewable energy installations, the demands placed on switching devices like GTO thyristors and IGBTs are greater than ever. Yet, behind these technological marvels lies an invisible enemy: electrical transients. Spikes in voltage and abrupt surges in current can devastate sensitive components, causing failures, costly repairs, and system downtime.

That’s where the importance of power electronics capacitors, especially GTO snubber capacitors, becomes evident. These capacitors serve as the protective shield for vital semiconductor devices, transforming potentially damaging electrical disturbances into manageable energy, thus preserving the integrity and reliability of the entire system.

GTO thyristors are powerful devices capable of handling substantial current and voltage in demanding applications. They offer fast switching capabilities, enabling precise control over power flow in systems like traction inverters, large motor drives, and renewable energy converters. However, with great power comes significant vulnerability.

During rapid switching, GTO devices face extreme rates of voltage change and sudden current surges. Without adequate protection, these electrical stresses can cause insulation breakdowns, unwanted triggering, or even catastrophic device failure. Engineers who work with GTO-based systems understand that the question is not if voltage spikes will occur—but how to manage them safely.

This is where GTO snubber capacitors prove invaluable. Acting as protective barriers, they absorb excessive energy and smooth out dangerous transients, ensuring that GTO thyristors operate safely within their limits.

A GTO snubber capacitor is designed to handle fast, high-energy transients that appear each time a semiconductor device switches on or off. When a GTO turns off, the energy stored in circuit inductances seeks an outlet. If left uncontrolled, this energy becomes a sudden surge of voltage across the GTO, threatening its safe operation.

GTO snubber capacitors provide a path for this energy, absorbing it and releasing it gradually. In doing so, they prevent excessive voltage spikes, reduce rapid changes in voltage and current, and help maintain the stable operation of the circuit. This directly contributes to the longevity and reliability of the GTO devices and the overall system.

Moreover, snubber capacitors help reduce electrical noise and electromagnetic interference, which is critical in modern systems where power quality and signal integrity are increasingly vital. In high-power applications, even minor disturbances can propagate across circuits and disrupt performance. GTO snubber capacitors serve as a buffer, shielding both the semiconductor and the system from harmful transients.

Neglecting proper snubber design comes with a hidden price. While initial cost savings might seem attractive, the long-term consequences can be devastating. Systems that lack adequate GTO snubber capacitors are more prone to unexpected failures, leading to unscheduled maintenance, production losses, and damaged reputations.

Consider an industrial environment where a converter system runs continuously. Without reliable snubber protection, voltage spikes could lead to repeated stress on GTO devices. Over time, this causes gradual degradation of the semiconductor, leading to insulation breakdowns or sudden failures. The financial impact of system downtime far exceeds the modest investment in quality snubber capacitors.

For engineers focused on system reliability and lifecycle cost, investing in robust GTO snubber capacitor solutions is not optional—it’s essential insurance against avoidable failures.

Selecting the right GTO snubber capacitor requires more than matching voltage ratings. Several critical properties determine whether a capacitor can truly protect sensitive devices under real-world operating conditions.

Low Equivalent Series Resistance (ESR)

Low ESR minimizes internal heating during rapid charge and discharge cycles. In high-frequency switching applications, capacitors with lower ESR maintain stable performance without excessive energy loss.

Low Equivalent Series Inductance (ESL)

Reduced ESL enables the capacitor to respond swiftly to voltage spikes, absorbing transient energy before it can damage the semiconductor device.

High dv/dt and di/dt Withstand Capability

A GTO snubber capacitor must endure sharp changes in voltage and current without degradation. This resilience is vital to maintaining protection during fast switching events.

Mechanical Robustness

Applications such as railway systems or industrial drives often involve vibrations and physical shocks. A capacitor’s construction must ensure stable electrical performance even under these mechanical stresses.

Reliable Dielectric Technology

Film capacitors, like those used by CRE, offer excellent pulse handling, minimal dielectric losses, and a stable performance across varied temperatures. Polypropylene film, in particular, provides strong insulation properties and high reliability.

In this context, CRE’s snubber capacitors stand out for their use of double-sided metallized film, dry resin infusion, and specialized winding techniques that result in low losses, high pulse current capability, and long operational lifespans.

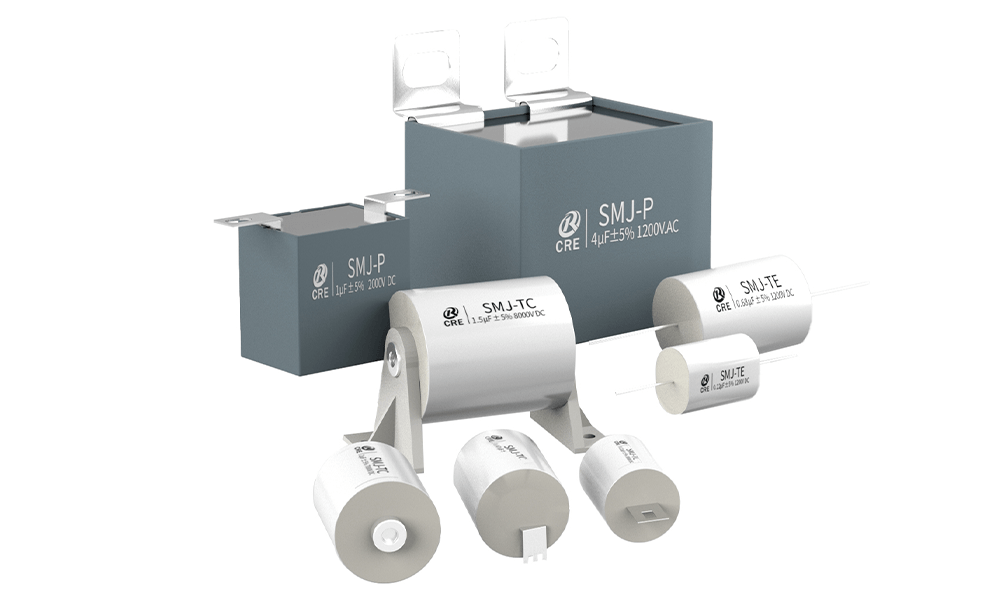

CRE has engineered a range of GTO snubber capacitors specifically for high-power, high-voltage environments. Their designs reflect a deep understanding of the challenges engineers face when protecting sensitive semiconductor devices.

For example, CRE’s Myra tape encapsulated GTO snubber capacitors are compact and easy to install, thanks to their copper nut leads and robust packaging. This combination ensures not only electrical performance but also mechanical stability under demanding conditions.

The low ESR and low ESL of CRE capacitors allow them to manage high-frequency currents effectively while withstanding significant voltage and current transients. Such characteristics make them particularly suitable for applications like:

Traction systems, where high pulse currents and mechanical vibrations are constant challenges.

Industrial drives, where rapid switching demands components that can maintain performance without overheating.

Renewable energy converters, where grid disturbances can introduce sudden transients requiring fast-responding protection.

Energy storage systems, where rapid charging and discharging cycles place significant stress on power electronics.

CRE’s snubber capacitors also benefit from a dry resin infusion technique, providing excellent insulation properties and long service life. This ensures consistent performance, even in environments with significant thermal fluctuations.

While choosing the right capacitor is essential, integrating it into the overall circuit design is equally important. Engineers must calculate the energy stored in inductive elements, estimate expected voltage overshoots, and select capacitor values that prevent harmful transients without introducing excessive current surges.

Moreover, thermal management plays a crucial role. Even the best GTO snubber capacitors can degrade over time if excessive heat is not properly dissipated. Factors like airflow, mounting methods, and proximity to heat-generating components influence the long-term stability of the capacitor.

Testing and validation remain indispensable steps. Engineers should simulate worst-case scenarios to ensure that the capacitor performs reliably across all expected operating conditions. In high-power applications, such diligence can mean the difference between flawless operation and costly system failures.

The modern world relies on complex systems that push power electronics to their limits. From transportation networks to renewable energy, countless sectors depend on the protective functions of GTO snubber capacitors.

In railway traction systems, inverters must handle significant power surges when accelerating or braking, often under harsh mechanical stress. Here, a reliable snubber capacitor is essential to maintain service reliability.

Industrial processes depend on precise control of large motors and converters. Rapid switching generates frequent transients that threaten the longevity of sensitive components, underscoring the need for dependable snubber protection.

Renewable energy installations face grid fluctuations and rapid changes in power flow. Wind gusts or varying sunlight can create electrical disturbances that would be harmful without effective transient suppression.

In energy storage systems, fast charging and discharging impose severe electrical stress. A robust GTO snubber capacitor ensures these systems operate safely and reliably under intense conditions.

The demands on snubber capacitors continue to grow as power electronics push into higher voltages, faster switching speeds, and more compact designs. Manufacturers like CRE are responding with innovations in materials, winding techniques, and encapsulation methods that enhance capacitor performance and longevity.

Emerging trends include the use of advanced film materials that further reduce losses and withstand even more severe transients. There is also a growing emphasis on integrating capacitors directly into power modules, saving space and minimizing stray inductance.

Additionally, environmental responsibility is influencing capacitor design. Manufacturers are moving towards greener materials and more sustainable production processes without compromising performance.

Such advances ensure that GTO snubber capacitors will continue to serve as crucial protectors in the ever-evolving landscape of power electronics.

GTO thyristors represent power and speed—but also a significant vulnerability to the harsh realities of electrical transients. Without effective protection, even the most advanced systems are at risk of sudden failures and costly downtime.

GTO snubber capacitors, especially those engineered by CRE, provide a vital line of defense. They manage voltage surges, reduce switching stress, and preserve the integrity of sensitive semiconductor devices. Investing in high-quality snubber solutions is not merely a design choice; it is a strategic decision that defines whether systems remain reliable under pressure.

As power electronics continue to evolve, the role of snubber capacitors becomes ever more critical. By choosing robust, well-designed solutions like those offered by CRE, engineers ensure that high-performance systems deliver not just power—but lasting reliability and peace of mind.