- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

In modern power electronics, film capacitors have become indispensable components, prized for their stability and efficiency under demanding conditions. Among these, resonance capacitors play a crucial role in shaping the performance of high-frequency circuits. Whether in switching power supplies, renewable energy converters, or industrial drives, these capacitors enable precise energy control and minimize losses, ensuring systems run with maximum reliability and efficiency.

Unlike standard capacitors, resonance capacitors are designed to work in tandem with inductors, creating resonant circuits that can store and transfer energy at specific frequencies. This resonant behavior is essential in power electronics, as it allows circuits to operate with lower losses and greater efficiency.

In high-frequency resonance capacitors, the design focuses on low equivalent series resistance (ESR) and minimal dissipation, helping systems achieve stable performance even when subjected to rapid voltage and current changes. This makes them especially valuable in applications requiring precise frequency control and energy optimization.

The Science Behind High-Frequency Resonance Capacitors

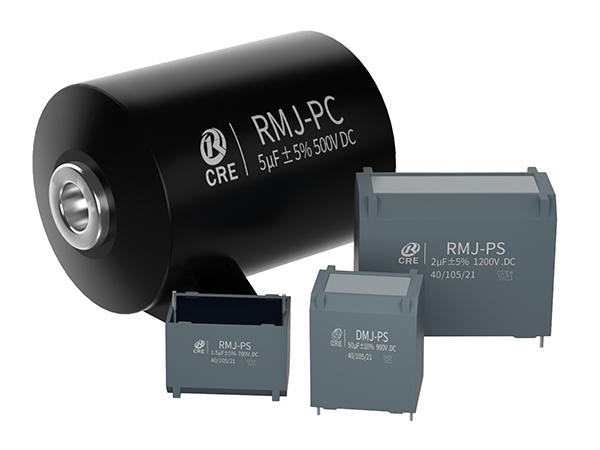

The Science Behind High-Frequency Resonance CapacitorsAt the heart of resonance capacitors in power electronics lies sophisticated materials engineering. Many of these capacitors are built with metallized polypropylene film, chosen for its excellent electrical properties. This material offers low dielectric losses and remarkable thermal stability, enabling the capacitor to maintain consistent performance at high frequencies and elevated temperatures.

One of the standout features of metallized polypropylene resonance capacitors is their self-healing capability. When a localized breakdown occurs in the dielectric, the metallized layer vaporizes around the fault, isolating the defect and restoring the capacitor’s functionality. This self-healing property greatly enhances reliability and extends the lifespan of the capacitor, making it suitable for demanding environments in industrial and automotive applications.

Across the power electronics landscape, resonance capacitors have carved out a critical niche. In LLC resonant converters, these capacitors define the resonant frequency and shape the transfer characteristics of the power stage. Their ability to handle high currents and voltages ensures efficient energy transfer while reducing switching losses.

In snubber circuits, resonance capacitors absorb voltage spikes and suppress oscillations, protecting devices like IGBTs and MOSFETs from potentially damaging transients. Their low ESR and high pulse-handling capabilities make them indispensable in these high-stress applications.

Beyond these, high-frequency resonance capacitors play vital roles in switching power supplies, industrial drives, solar inverters, and even in emerging fields like wireless power transmission. Engineers rely on their precision and stability to ensure systems operate safely and efficiently under variable loads and challenging conditions.

Choosing the right resonance capacitors is essential for achieving optimal performance in power electronic systems. One of the first considerations is matching the capacitor’s characteristics to the desired resonant frequency of the circuit. Capacitance value, ESR, and voltage rating all influence how efficiently the circuit resonates and transfers energy.

Temperature performance is another critical factor. As operating temperatures rise, the electrical properties of a capacitor can shift, potentially impacting resonance and efficiency. Designers often look for capacitors rated for stable operation under high temperatures, ensuring reliability even in harsh environments.

Equally important is the capacitor’s ability to withstand high ripple currents without excessive heating. A low dissipation factor ensures that energy losses remain minimal, while high insulation resistance preserves safety and performance over time.

For applications like snubber circuits, fast pulse response and high peak current capabilities are crucial. Capacitors must be able to absorb and release energy quickly to suppress voltage spikes and protect sensitive components. Engineers also pay attention to physical size constraints, balancing performance with the need for compact designs, especially in modern, high-density power electronics.

Even with high-quality film capacitors for resonant circuits, designers face several challenges. One major issue is heat generation, particularly in high-frequency operations where even small losses can translate into significant thermal stress. Using resonance capacitors with low ESR and excellent thermal properties helps mitigate these effects.

Another challenge is ensuring the stability of the resonant frequency. Variations in temperature, aging of materials, or manufacturing tolerances can shift a circuit’s resonant point, potentially reducing efficiency or causing unwanted noise. Selecting high-frequency resonance capacitors with tight tolerance specifications helps maintain circuit performance over time.

Electromagnetic compatibility (EMC) is also a growing concern in modern electronics. The fast switching edges common in resonant circuits can introduce noise that affects nearby systems. Capacitors with well-controlled parasitic properties can help reduce these emissions, improving overall system compliance with EMC standards.

Cost and space constraints further complicate design choices. While metallized polypropylene resonance capacitors offer excellent performance, they can be larger or more expensive than alternative technologies. Engineers must weigh these trade-offs carefully, considering both immediate performance and long-term reliability.

As technology evolves, the role of resonance capacitors in power electronics is expanding into new territories. Electric vehicles are pushing demands for higher efficiency and power density, requiring capacitors that can operate under extreme thermal and electrical conditions. Similarly, renewable energy systems demand components that maintain stable performance under fluctuating loads and harsh environments.

Emerging technologies like wireless power transfer and ultra-fast charging also rely heavily on precise resonant circuit design. In these applications, high-frequency resonance capacitors are critical for minimizing losses and achieving the energy transfer needed for practical implementations.

Manufacturers are continually innovating to deliver capacitors with smaller footprints, higher reliability, and enhanced thermal properties. As the market for advanced electronics grows, resonance capacitors will remain a cornerstone of efficient, high-performance systems.

From industrial drives to next-generation automotive systems, resonance capacitors are essential tools for engineers seeking to optimize performance, reduce losses, and ensure the longevity of their designs. With advancements in materials and manufacturing, today’s film capacitors for resonant circuits offer exceptional reliability and efficiency, even under the most demanding conditions.

For any application where energy efficiency and precision are paramount, resonance capacitors in power electronics deliver the performance and stability required to meet modern engineering challenges. As power systems become more compact and efficient, these components will continue to shape the future of energy management across diverse industries.