- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-06-19 Origin: Site

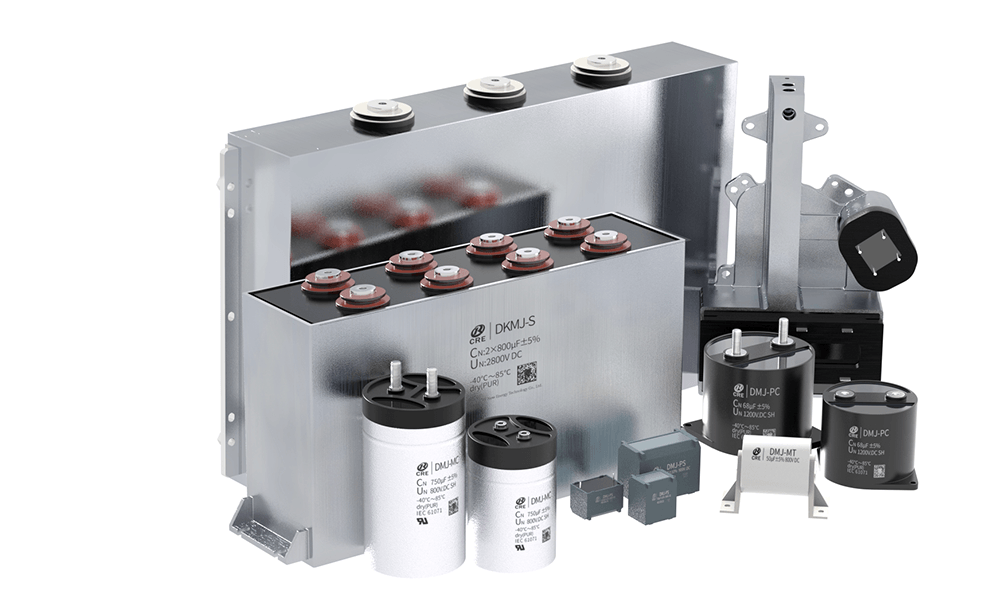

The rapid evolution of modern power converters has ushered in an era where efficiency, reliability, and compactness are paramount. Central to achieving these objectives is the advancement of high voltage DC link capacitors, which are instrumental in stabilizing voltage levels, filtering noise, and ensuring the seamless operation of power electronic systems. As industries such as renewable energy, electric vehicles, and smart grids continue to expand, the demand for sophisticated DC link capacitors has never been greater. This article delves into the cutting-edge solutions that high voltage DC link capacitors offer to modern power converters, exploring their design considerations, materials, and applications.

DC link capacitors are critical components in power electronic converters, serving as energy storage devices that smooth out voltage ripples and provide a stable DC voltage to the inverter stage. They are placed between the rectifier and inverter circuits, acting as a buffer that absorbs the pulsating DC output from the rectifier. This buffering is essential for minimizing voltage fluctuations that can lead to inefficiencies or damage in sensitive electronic components.

In power converters, the performance of DC link capacitors directly impacts the overall efficiency and reliability of the system. They help in reducing harmonic distortion and electromagnetic interference (EMI), which are crucial for meeting industry standards and regulations. By providing a low-impedance path for high-frequency currents, these capacitors suppress voltage spikes and transients that can occur due to rapid switching actions inherent in power electronic devices.

When selecting DC link capacitors for high voltage applications, several key specifications must be considered:

Capacitance Value: Determines the ability to store charge and smooth voltage ripples.

Rated Voltage: Must exceed the maximum voltage expected in the application to prevent breakdown.

Equivalent Series Resistance (ESR): Lower ESR reduces power losses and heating within the capacitor.

Thermal Performance: Adequate thermal management ensures longevity and reliability under high operating temperatures.

Advanced Materials and Technologies

Advanced Materials and TechnologiesThe advancement of high voltage DC link capacitors is closely tied to the development of new materials and manufacturing technologies. Innovations in dielectric materials, such as polypropylene films, have significantly improved the electrical properties and reliability of these capacitors.

Polypropylene film capacitors have become the industry standard for high voltage applications due to their excellent electrical characteristics. They offer low dielectric loss, high insulation resistance, and superior thermal stability. The self-healing properties of metallized polypropylene films enhance the longevity of the capacitors by allowing them to recover from dielectric breakdowns caused by voltage spikes.

Recent advancements have led to the development of ultra-thin films, which increase the capacitance per unit volume, allowing for more compact capacitor designs without compromising performance. This miniaturization is crucial for applications where space is at a premium, such as in electric vehicles and aerospace equipment.

Emerging research into nanocomposite dielectrics is paving the way for capacitors with even higher energy densities and better thermal performance. By incorporating nanoparticles into the polymer matrix, it is possible to tailor the dielectric properties to meet specific application requirements. These materials exhibit enhanced breakdown strength and can operate at higher temperatures, making them ideal for demanding environments.

Designing high voltage DC link capacitors for modern power converters involves balancing several factors to achieve optimal performance. Manufacturers must consider electrical, thermal, mechanical, and environmental aspects during the design process.

Capacitors must be designed to handle the electrical stress imposed by high voltage levels and rapid voltage changes. This involves selecting appropriate dielectric materials and thicknesses to withstand the maximum expected voltages. Additionally, design strategies such as grading layers and edge terminations can help mitigate electric field concentrations that may lead to premature failure.

Effective thermal management is essential to ensure the reliability of high voltage DC link capacitors. Heat generated by dielectric losses and ESR must be dissipated efficiently to prevent thermal runaway. This can be achieved through the use of heat sinks, cooling systems, and by optimizing the capacitor's physical design to enhance heat transfer.

Advanced simulation tools are often employed to model thermal behavior under various operating conditions. By predicting temperature gradients within the capacitor, designers can make informed decisions to improve thermal performance and extend the lifespan of the component.

Capacitors used in industrial and automotive applications must withstand mechanical stresses such as vibration and shock. Robust housing materials and secure mounting methods are necessary to prevent physical damage. Environmental factors like humidity, dust, and chemical exposure also influence the design, necessitating protective enclosures and sealing techniques.

The integration of high voltage DC link capacitors in renewable energy systems, such as solar inverters and wind turbine converters, is crucial for efficient energy conversion. These systems require capacitors capable of handling high power levels and fluctuating input conditions while maintaining stability.

In photovoltaic (PV) installations, DC link capacitors help in smoothing the DC output from solar panels before it is converted to AC by the inverter. They must be capable of operating under high temperatures due to exposure to sunlight and must exhibit low losses to maximize system efficiency. The use of advanced high voltage DC link capacitors enhances the reliability of solar inverters, contributing to the overall performance of PV systems.

Wind energy systems utilize DC link capacitors in their power converters to manage the variability of wind speeds and power outputs. These capacitors must handle large fluctuations in voltage and current while maintaining stability. Moreover, they need to be durable enough to withstand harsh environmental conditions, including extreme temperatures and humidity.

The rise of electric vehicles (EVs) has placed new demands on DC link capacitors used in onboard chargers and traction inverters. The need for compact, lightweight, and efficient components is driving innovation in capacitor technology.

Onboard Chargers

Onboard ChargersOnboard chargers convert AC power from the grid into DC power to charge the vehicle's battery. DC link capacitors in these chargers must handle high power densities and support fast charging capabilities. Advanced capacitors with high dielectric strength and thermal stability are essential to meet these requirements and to ensure safety and reliability.

Traction inverters convert DC power from the battery into AC power to drive the electric motors. The performance of the DC link capacitor significantly affects the inverter's efficiency and the vehicle's overall performance. Innovations in capacitor technology contribute to longer driving ranges, improved acceleration, and better energy management in EVs.

Manufacturers are focusing on developing capacitors with higher energy densities and lower ESR to meet the stringent demands of the automotive industry. The adoption of these advanced high voltage DC link capacitors is a key factor in the evolution of electric vehicle technology.

In industrial settings, maintaining high power quality is essential for the efficient operation of machinery and equipment. DC link capacitors play a significant role in mitigating power disturbances and improving the performance of variable frequency drives (VFDs), uninterruptible power supplies (UPS), and other critical systems.

VFDs control the speed of motors by varying the input frequency and voltage. DC link capacitors in VFDs help reduce voltage ripples and provide a stable DC bus voltage, which is necessary for precise motor control. High-performance capacitors enhance the efficiency of VFDs, leading to energy savings and reduced operational costs.

UPS systems rely on DC link capacitors to store energy and provide a clean power supply during interruptions. The capacitors must have high reliability and longevity to ensure continuous operation of critical infrastructure. Advances in capacitor technology contribute to the development of UPS systems with longer backup times and improved power conditioning.

Ensuring the reliability of high voltage DC link capacitors involves rigorous testing and quality control measures. Testing protocols are designed to simulate operating conditions and identify potential failure modes.

Electrical testing includes measuring capacitance, ESR, insulation resistance, and dielectric strength. Accelerated life tests subject capacitors to elevated voltages and temperatures to assess their long-term reliability. Partial discharge testing is used to detect imperfections in the dielectric material that could lead to breakdown.

Environmental tests expose capacitors to conditions such as temperature cycling, humidity, and mechanical vibration. These tests ensure that the capacitors can withstand the stresses encountered in real-world applications. Compliance with industry standards and certifications is often required for capacitors used in critical applications.

The ongoing advancement in high voltage DC link capacitor technology is driven by the need for higher efficiency, greater reliability, and reduced size. Several trends are shaping the future of these critical components.

The integration of monitoring and diagnostic capabilities into capacitors is gaining traction. Smart capacitors equipped with sensors can provide real-time data on operational parameters such as temperature, voltage, and current. This information enables proactive maintenance and can prevent unexpected failures, enhancing system reliability.

Research into novel dielectric materials, including polymers and ceramics with superior properties, is opening new possibilities for capacitor performance. Materials with higher dielectric constants and breakdown strengths can lead to capacitors that are smaller and more efficient, meeting the growing demands of compact electronic systems.

There is a growing emphasis on the environmental impact of electronic components. Manufacturers are exploring eco-friendly materials and production processes to reduce the carbon footprint of capacitors. Additionally, the recyclability of capacitor materials is becoming an important consideration in the product lifecycle management.

High voltage DC link capacitors are indispensable components in modern power converters, enabling efficient and reliable power conversion across a wide range of applications. Advances in materials, design methodologies, and manufacturing technologies continue to enhance their performance, supporting the growth of industries such as renewable energy, electric vehicles, and industrial automation. By understanding the critical role of DC link capacitors and staying abreast of technological developments, engineers and professionals can make informed decisions that optimize system performance and contribute to the advancement of power electronics.